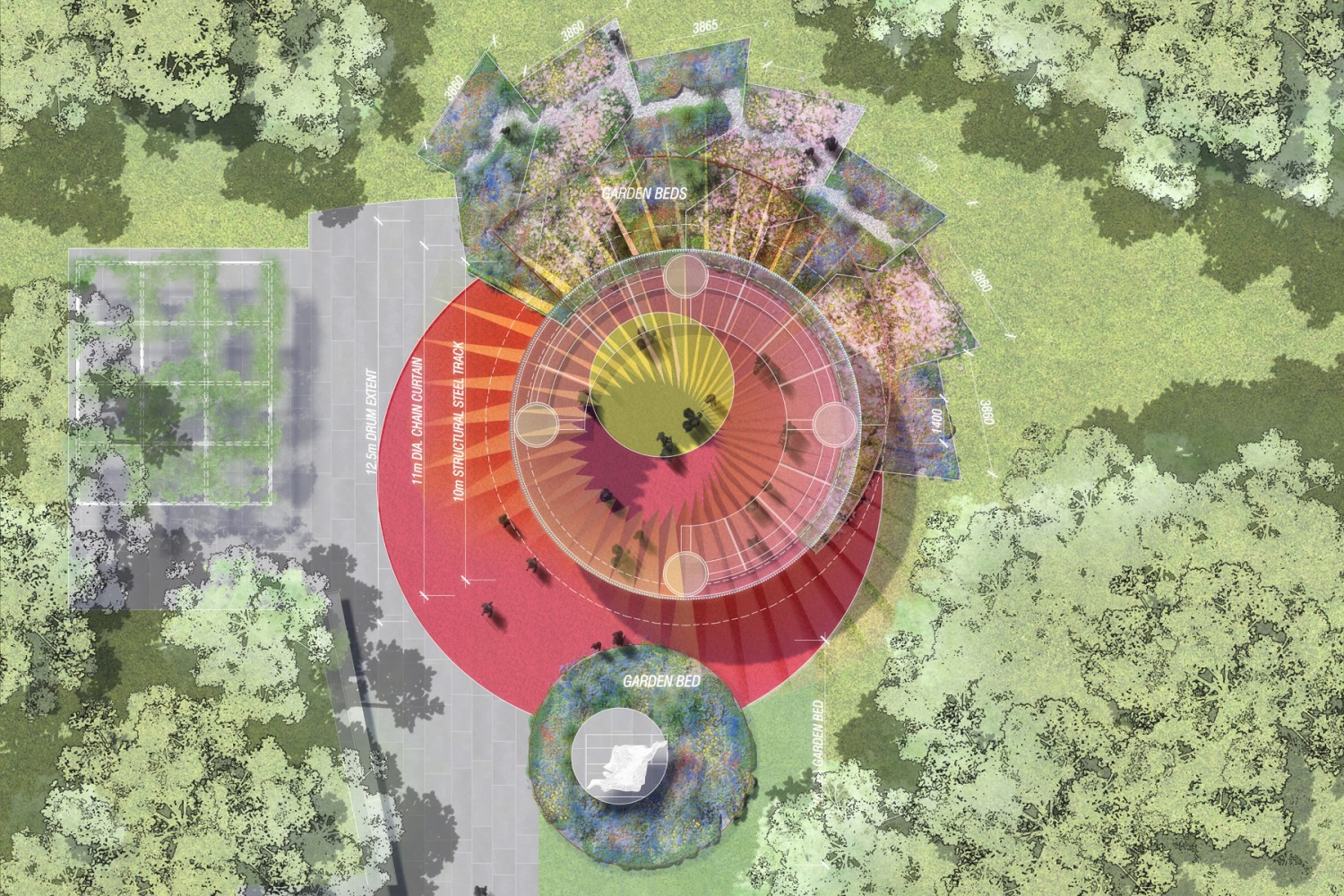

In collaboration with structural engineer Peter Felicetti and artisan steel fabricator Ian Webb (Webb Welding), the main structural components of the pavilion will be galvanised steel for both its ease of local & off-site fabrication and to achieve the required spans & kit of parts attributes. To support the proposed feature rotating drum, a foundation of four ballast cylinders (filled with rubble on-site) will create a solid base that does not require excavation. Four rolled steel ‘tracks’ composed of top, bottom, and integrated caster wheels (the bearings) are craned individually and mechanically fixed to the foundations to create a continuous ring.

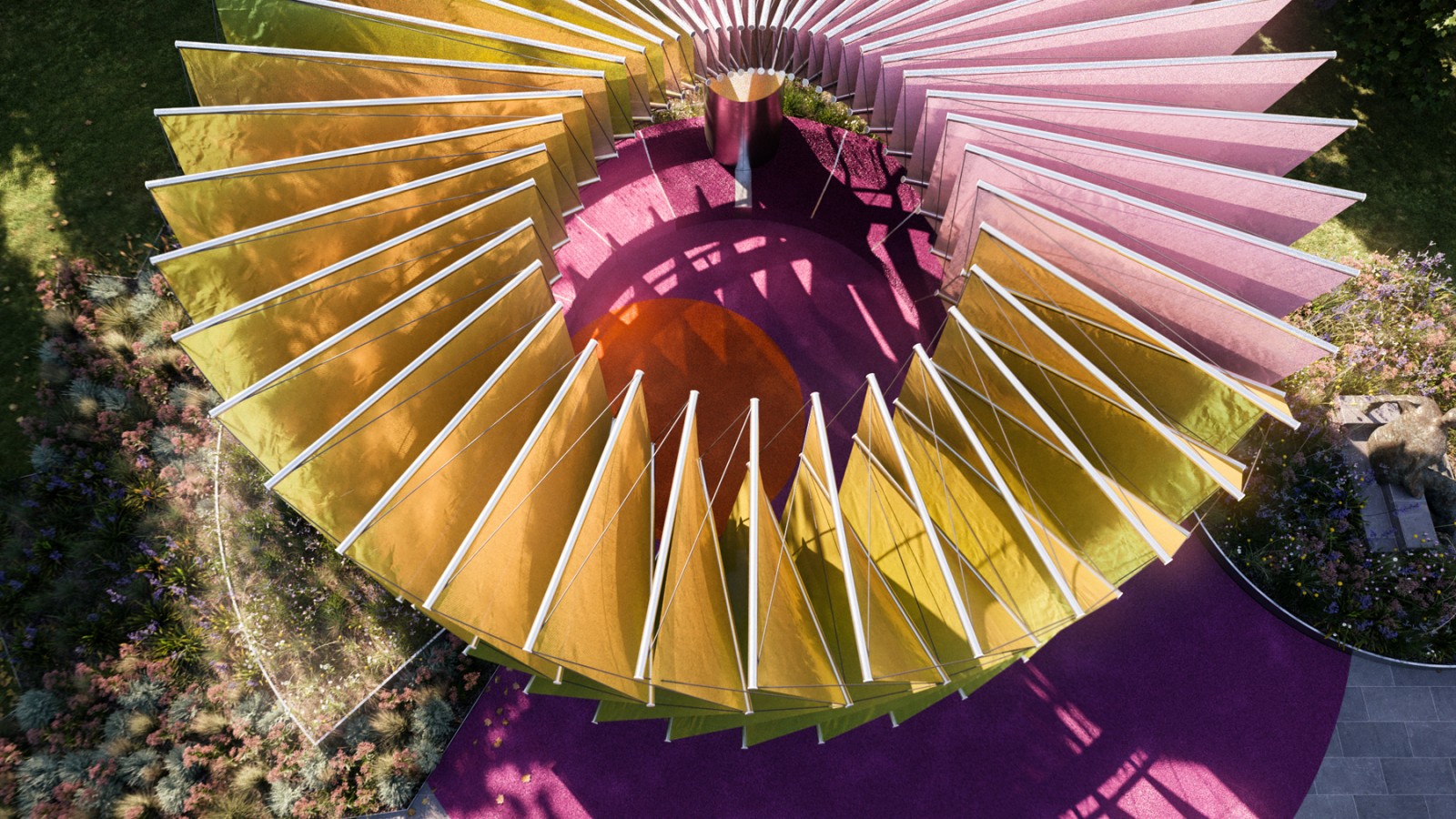

Forty-two faceted and interlocking ‘fins’ form the feature drum of Simply Irresistible. Working with Oasis Tension Structures, experts in tensile structures, each fin comprises two iridescently coloured stretched sail shades supported with top, middle and bottom tubular extrusions and discreet fixings. These extrusions are capped in trailer reflectors for a shimmering effect. Each lightweight fin is lifted into place and fixed to its neighbour with cables to form a continuous self-supporting tensegrity ring.

The gentle rotation of the drum will be achieved kinetically as a wind turbine. On calm days, movement will be achieved using a proprietary gate motor discretely located above one of the foundation cylinders adjacent to the steel track. The motor will be powered via surplus energy stored in a battery. The motor and the rotating drum can be switched on and off with remote control depending on the time of day and prevailing weather conditions.

A fringe of zinc-plated ‘single jack’ metal chains create a soft circular screen for the pavilion. Chains are fixed to a tubular steel element at the top and a partially submerged bottom rail. A small section near the entry will be unfixed to allow people to pass through or open for special events.